What’s the purpose of real-time Statistical Process Control (SPC)? The quick answer is that it’s used to monitor production processes and leverage that important information to improve product quality.

And how exactly does SPC help with that? By helping you to regularly collect, monitor, and analyze production data. An important part of that analysis is providing process alerts and notifications to operators, inspectors, quality professionals, and managers. By analyzing data and triggering process alerts, SPC software

communicates in real time to the right people when issues arise, reducing or eliminating risk, waste, and defects.

So, step one (from my previous blog, “Optimize SPC Data Collection”) was to effectively use SPC to get a fresh look at the data. Once data is being collected on the shop floor with a modern, real-time SPC solution, we need to determine what alerts and alarms should be enabled, such as when:

- Operators and inspectors are required to gather data

- Process performance changes significantly (statistical alarms that define out-of-control conditions)

- Data falls outside of control limits (engineering specification limits that define a product’s acceptability)

Why are these notifications so important? They allow your SPC software to give you information that can prevent trouble—or minimize its impact—before issues negatively affect your bottom line.

Notifications When SPC Data Collection Is Required

SPC-based quality management can set the stage for significant process and product improvements, but only if you get the data you need. That’s why it is so important that the right data gets gathered at the right time.

Let’s face it, there is going to be downtime in your manufacturing processes. During those times, data collections are expected to be delayed or even missed. But when the factory is humming, data needs to be gathered. Whether for compliance reasons or to better understand process behaviors, you need data.

But if you’re collecting data on paper, beware—data may not be gathered when you need it to be. And best practices might not even be followed.

That’s where quality management software comes in. Your SPC system needs to be able to provide reminders to operators and inspectors when data collections are required. Regarding notifications, real-time SPC software should—

- contain lots of flexibility, enabling you to configure scheduled, regularly-occurring quality checks at different times of the day and in different areas of the plant;

- let you know if those data collections didn’t occur as scheduled; and

- generate reports to tell you what was missed and why.

Timed notifications help to ensure that samples, inspections, and quality checks aren’t forgotten and that they occur when they need to.

Say you need data from a specific product feature to be collected each hour. Instead of asking your busy operators to remember to gather data every 60 minutes, you can set a reminder so that they can instead concentrate on their production tasks and forget about watching the clock. That’s because the software remembers when data collections are due and reminds operators, relieving them of the burden to remember.

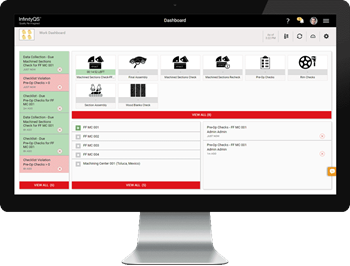

Solutions like InfinityQS® Enact® filter notifications according to user role. Enact uses dashboard tiles to highlight the notifications based on who is signed in and their specific responsibilities.

This unique, highly visual SPC solution ensures that users see only the information they need, when they need it. Timed notifications can take the form of:

- countdown timers in the Enact interface

- emails

- dashboard icons indicating number of notifications

- notification windows that turn different colors based on data collection status

Learn how dashboards make it easy for users to quickly find the information they need to work effectively. Watch the video.

Notifications when Process Performance Changes Significantly

Your SPC software should generate an alert the moment data violates a statistical alarm rule. Operators should be notified in real-time, and so should engineers, support staff, and even you.

Real-time SPC process alerts can help you mitigate the damaging consequences of excessive variation, unsafe products, unbalanced ingredients, and more. Whether visual or auditory, alerts should be able to catch the user’s attention and reach them wherever they are, whenever a violation occurs.

Notifications when Data Falls Outside of Control Limits

Operators and quality professionals all try to prevent this situation. No one wants to create products that violate engineering specifications. But it happens sometimes—even with the finest quality management systems and the best oversight and support. When it happens, you need notifications to reach the right people.

Engineering, management, quality, and other support personnel should receive notifications in real time telling them exactly what product violated the spec, and where and when the violation occurred. This minimizes additional out-of-spec violations and helps your company to isolate and remove the root cause of those issues.

One InfinityQS customer saw a 66% annual dollar savings from reduced scrap alone. Read the Case Study.

Get the SPC Process Alerts and Notifications You Need

Don’t miss out on the communication value that a real-time SPC software solution can provide. Real-time notifications can ensure that data is collected precisely when you need it to be. Plus, your SPC software should be able to alert your team immediately when issues occur or violations are triggered on the shop floor.

You’ll want to choose an SPC solution that provides simple configuration of notifications, automatic alarming, emailing, and robust process alerts and notifications that keep operators and quality users focused and ahead of potential quality issues.

Read the other blogs in this series:

Optimize SPC Data Collection: Mastering Quality #1

Stay on Track with SPC Process Alerts and Notifications: Mastering Quality #2

What’s Your Priority? Use SPC to Maximize Your Impact on Quality and Costs: Mastering Quality #3

Analyzing Quality Data with the Right SPC Tools: Mastering Quality #4

Reporting & Communicating SPC Data for Change: Mastering Quality #5

Would you like to see how these techniques can be applied to your organization? Schedule a live demo, customized to your organization and requirements.