In the first two blogs of our Data Collection series, we looked at manual and semi-automated data collection. Specifically, we discussed how InfinityQS® Enact®—a comprehensive quality intelligence solution—provides a data collection software solution that makes both manual and semi-automated data collection easy and helps users focus on what’s important for them to do their jobs.

For this, our third and final blog in the series, we’ll turn our attention to fully-automated data collection, describe why it’s so powerful, and explain how easy it is with Enact.

What is fully automated data collection?

Well, pretty much what you’d think. Data is automatically collected, without prompting or any manual (human) action.

How to automate data collection? DMS and DCS

These two tools have been around for almost a decade. And their track records are great. DMS is the piece that actually talks to the equipment; it receives data values from checkweighers, text files, databases (ERP, MES, CMMs, etc.—Enterprise Resource Planning, Manufacturing Execution System, and Coordinate Measuring Machine, respectively), and OPC servers (okay, here we go: OPC is a twisted, painful acronym—it stands for OLE for Process Control; and, of course, OLE stands for Object Linking and Embedding—what else, right?). Most of us use OPC servers and have no idea what it stands for. Here’s a link, if you’re really interested (but maybe read the rest of the blog before you click away). They (OPC servers) are the most common way to read from programmable logic controllers (PLCs). Whew! Sometimes acronyms can just wear you out. In a nutshell, DMS essentially “harvests” the data from various sources.

DCS takes all the information that DMS harvests and combines (or standardizes) it for use in Enact. (In actuality, these tools work for both of InfinityQS’ quality solutions: ProFicient™ and Enact.)

An important thing to keep in mind is that by utilizing both DMS and DCS in your quality improvement system you can marry all the separate, disparate data together; Enact can then display it in a useful, easy-to-understand fashion. And remember that in Enact data is data, so your fully-automated data can be viewed and analyzed the same way your manual and semi-automated data. (In the graphic below, red is manually collected data, blue is semi-automated, and green is fully-automated.)

The advantages of fully-automated data collection

Enact is a quality intelligence platform that helps you understand how your manufacturing processes affect your end-products. If we understand our process well enough, we can measure that process and detect problems before a product is affected. Fully-automated data collection is an important part of any data collection effort; it eliminates human errors. Is there anything worse than “fat fingering” a data entry? You meant to press a 7 there, but instead you pressed 6 and now the data is incorrect and messes up your whole analysis. And, perhaps most importantly, fully-automated data collection frees your operators from having to manually enter data, so they can focus on the myriad other tasks they need to keep an eye on.

Let’s use cookie manufacturing as our example of how fully-automated data collection can help you with your quality improvement endeavors. Ideally, you want all your cookies to taste the same, and have the same crunchiness or chewiness. With Enact—utilizing DMS and DCS—you can automatically measure oven temperature as well as moisture.

Sounds simple, but there’s more to it. Does your oven know what cookie is running through it at the moment (e.g., chocolate chip vs. sugar cookie)? Maybe it does, based on the recipe or setup being used, but often that’s not the case. Furthermore, does it know the production order that is currently being produced? This is where DMS can come to the rescue by allowing you to gather the temperatures and moistures from the sensors and combine them with the part from your ERP system and the current production order from your MES system. Finally, all of those separate pieces of information are combined in DCS to tell you that the temperature for the Chocolate Chip Cookies running through Oven 2 for Production Order 258 is exactly as you want it to be. There are several benefits of this.

In the short-term, notifications can be generated so users know right now if there is an issue and adjust the process before making any non-conforming product. This is how you can prevent costly product holds or, even worse, potential recalls.

In the long-term, you now have a way to study your data for trends to not only improve the consistency of your products, but look for opportunities to run your operations more economically. What if you could put one less cookie in every bag and still give your customers a full bag? In high-speed manufacturing those cookies add up to an extra bag very quickly, those bags become an extra pallet and each pallet brings in more money.

Improvements in your products, processes, and operations benefit your customers and your company.

Enact’s automated data collection software helps you control your production processes

Enact makes all of your data collection simple. It’s important to note that many quality systems are, in actuality, a collection of quality systems and data collection devices that have been cobbled together over the years. The big drawback to this jumble of systems is that individual pieces can’t or don’t talk to one another because their data formatting is so different, even proprietary. And because they don’t talk to one another, it’s nearly impossible to roll up all that data into a cohesive, “big picture” of quality.

Since Enact is a software-as-a-service (SaaS) quality platform, data is easy to manage. All data values (whether from different product codes, production lines, or plants) are saved in one place—a centralized data repository. With all your data in one place, you can easily keep track of, and control, your production processes.

Enact to the rescue

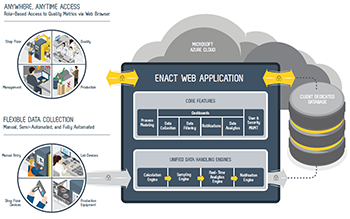

Getting your data from fully-automated sources cuts out the middleman, where errors occur. Enact has unified, centralized data handling engines, as you can see in the diagram below, which ensures that all that data that comes into the repository is seen the same. In Enact, data is just data.

All data, whether you type it in (manual), it comes from a gauge and you click Save (semi-automated), or it comes from a PLC (not an acronym again!), is treated the same. In all three cases, the data goes through the unified data handling engines. What this means is that—in Enact—everything is handled the same way, timed data collections are a snap, and based on your criteria, you are automatically notified of any spec-limit or statistical violations. Enact makes SPC data collection easy.

To learn more about Enact, click here.