With this blog, I hope to help shed some much-needed light on Acceptance Sampling, an important part of many manufacturing quality endeavors. Before we get started, I would just like to say that Acceptance Sampling, combined with statistical process control (SPC) techniques, can provide a serious boost to your organization’s process improvement program.

A Little History of Acceptance Sampling

Acceptance Sampling was created to refine manufacturing and reduce unacceptable lots. A sample is picked at random from the lot and, based on information that was yielded by the sample, a decision is made regarding the disposition of the entire lot. In general, the decision is either to accept or reject the lot. This process is called Lot Acceptance Sampling or just Acceptance Sampling.

It was first employed by the U.S. military during World War II to ensure that manufactured bullets were up to standards.

Acceptance Sampling is commonly used in the medical, automotive, and life sciences industries. Manufacturers use Acceptance Sampling when 100% inspection is too costly or time consuming, or when testing is destructive (to get inspection results, you have to destroy the product—you can’t do 100% inspection if you destroy the product!). Generally, it is used in these key manufacturing areas:

- Receiving inspection – bringing in materials or parts to make or assemble into your product

- Assembly – during which, depending on the rate of assembly (several parts per minute or more), you cannot practically do 100% inspection

- Final inspection

Acceptance Sampling Makes Sense

Manufacturing facilities are busy places. We all know that. You’ve got manufacturing processes running that might touch every aspect of a plant, from raw materials to injection and blow molding to labeling and packaging. There may be lids, or colors, or cleaning agents involved. So, rather than inspect everything that’s coming down the line, it makes sense to do sampling. Who has time to look at every piece? That’s just time and money.

That’s the basis of Acceptance Sampling. We don’t want to look at everything; we want to look at a sample, and we want that sample to be statistically derived. Makes sense, right?

Acceptance Sampling Terms

You Need a Glossary Just to Discuss It!

One of the first things you need to understand about Acceptance Sampling is the terminology. First and foremost: AQL. We use this term a lot in Acceptance Sampling. Let’s start with AQL and then discuss some other terms as well:

Acceptable Quality Limit is a specific Acceptance Sampling technique. To many who use the term, AQL is synonymous with Acceptance Sampling. AQL is the worst tolerable process average (or mean) in percentage ratio that is still considered acceptable (at an acceptable quality level).

Lot Tolerance Percent Defective (LTPD) is another common term. The LTPD of a sampling plan is a level of quality routinely rejected by the sampling plan. It is generally defined as that level of quality (percent defective, defects per hundred units, etc.) that the sampling plan will accept (generally) 10% of the time.

The LTPD method uses the following risks, depending on whether you are using variable or attribute samples:

Consumer Risk is a potential risk found in all consumer-oriented products, that a product not meeting quality standards will pass undetected through the manufacturer’s quality control system and enter the consumer marketplace.

Producer Risk is the risk that a good product will be rejected as a bad product by the consumer. Or the sampling plan will fail to verify an acceptable lot’s quality and, thus, reject it.*

And just a few more terms. These last few are associated with the ANSI and ISO standards:

You hear the term Inspection Level a lot when discussing Acceptance Sampling. An inspection level designates the relative amount of inspection required (i.e., sample size):

- General (3 total) – sample sizes range from 2 to 2000 pieces

- Special (4 total) – sample sizes range from 2 to 125 pieces

And last, Inspection State, which is the condition at which the sampling plan resides:

- Normal – where most inspection plans start

- Tightened – if 2 of 5 (or fewer) consecutive lots fail (refers to going to a tighter AQL, or worst tolerable process average—generally requires more samples during testing)

- Reduced – previous 10 lots accepted, total nonconforming less than the limit number, production level is steady, approved by a responsible authority (opposite of tightened—things are going well)

So, there’s our glossary. This will help with the rest of the discussion. Please refer back to these definitions when/if you need to.

InfinityQS and Acceptance Sampling

ProFicient™ is InfinityQS’ industry-leading real-time Statistical Process Control (SPC) solution. This software provides a comprehensive array of tools, so you can better understand the performance and capability of your vital manufacturing processes.

Regardless of your industry and the products you produce, ProFicient can provide your operators, engineers, quality team, and managers with the detailed, real-time SPC data they need to assess current operations and take appropriate proactive or remedial steps to maintain product quality, avoid costly scrap, and meet production goals.

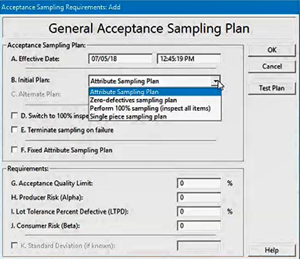

ProFicient offers a General Acceptance Sampling Plan, which utilizes sampling based on the LTPD method, using either variable or attribute data. The system also offers Custom Plans and additional Attribute Plans:

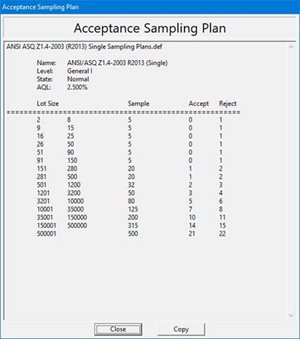

- ANSI/ASQ Z1.4 2003 R2013

- ISO 2859-1:1999(E) (Single)

- Zero Acceptance Number (Squeglia) – Table 1a – also known as C=0 (generally used in the automotive industry)

- Zero Acceptance Number (Squeglia) – Table 1b – also known as C=0 (generally used in the life sciences industry)

- Custom plans

All InfinityQS Acceptance Sampling plans allow 100% inspection on failure. All Attribute plans work with variable data. Additionally, ANSI/ASQ and ISO plans include the following options:

- Switching Rule Notification (example: switching from Normal to Tightened when necessary)

- Require Assignable Cause Code (ACC) – before switching inspection state

- Require Corrective Action Code (CAC) – before switching inspection state

- Automatically Switch Inspection State (Normal to Tightened and back to Normal only)

Okay, let’s get to the meat and potatoes of Acceptance Sampling. How does it work?

Acceptance Sampling at Work

So, the automotive industry operates under safety compliance, or regulated safety rules. That’s why they use AQL. The food and medical industries are regulated by the FDA because there’s human risk involved. Some food companies make supplements, which are not necessarily pharmaceutical but, in some cases, are held to the same standards. So, you can see why many industries use AQL.

In addition, many of our customers receive components from other manufacturers, and they occasionally use AQL to control the supply chain. They wouldn’t necessarily use it in the rest of their processes, but they would use it with parts coming in. This could apply to just about any company.

Using Acceptance Sampling on incoming parts is a measure of control on the supply chain. Why look at every sample coming in? Again, Acceptance Sampling makes great sense, especially when dealing with high volumes.

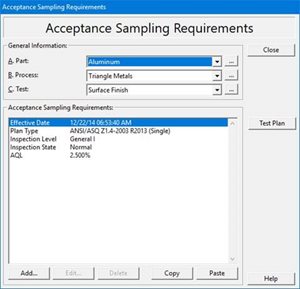

First things first—to use them, sampling plans must be defined internally anddocumented at your facility (i.e., you need a standard operating procedure for sampling). The minimum requirements you need to know to set up an inspection include:

- Part

- Process

- Test

- AQL (in most cases)

- The remainder depend on the Plan Type

Acceptance Sampling in ProFicient

So, let’s take a moment to explore what it might look like for an operator to perform data collection using Acceptance Sampling in ProFicient.

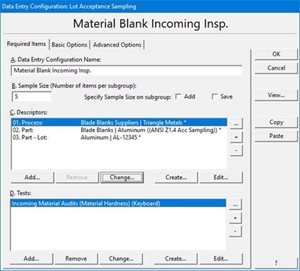

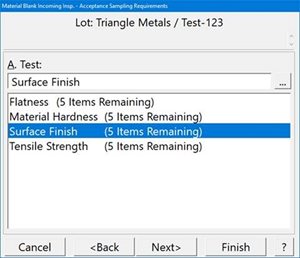

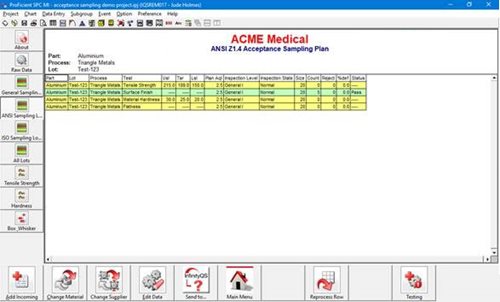

The following example and screen shots from ProFicient focus on a single part (Aluminum), from a single supplier (Triangle Metals), using a single test (Surface Finish). The requirements are captured in the screen shot below:

With this sampling requirement in place, any time I create a new lot with a specified Lot Size, inspecting the corresponding number of samples for Surface Finish will be required.

When the lot size is between 151 and 500, we see that at least one defect out of 20 samples is allowed. Now, how will this look in the software during data entry?

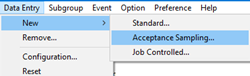

I’ve already configured a ProFicient™ Data Entry Project to collect data. The Data Entry Configuration is an Acceptance Sampling configuration, which allows it to access that table where I previously set up my Sampling Requirements.

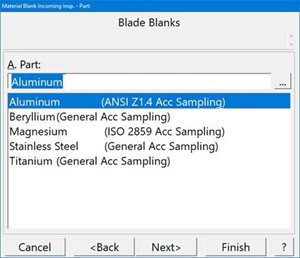

After I sign into the software and select my Data Entry Project and click the Add Incoming button, the software is going to ask for the Part:

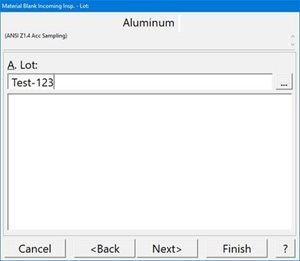

In this case, Aluminum is already highlighted (because it’s at the top of the list), which is what I want, so I’ll click Next. The software will now ask for a Lot:

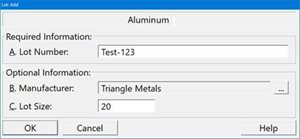

I’m going to type in a new lot called “Test-123” and click Next. Now the software prompts for the Lot Size:

I enter 20 and click OK. I have configured the Data Entry Configuration to reselect the Test for which I want to collect data; the following window displays:

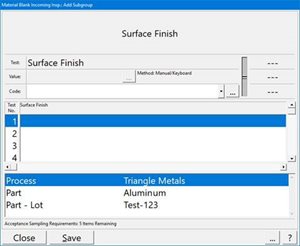

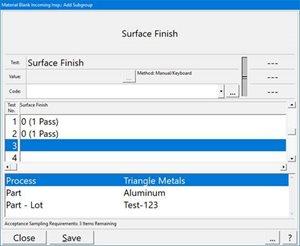

I can see that I have other Tests that are requiring a result, but I’m interested in Surface Finish, so I select that and then click Next. Surface Finish in this example is a Defective test (Pass/Fail). As I enter results, there is information at the bottom of the Data Entry Window telling me that there are x number of samples remaining:

In this example, I’m requiring all results be entered at one time. The software can be configured to use a flexible sample size.

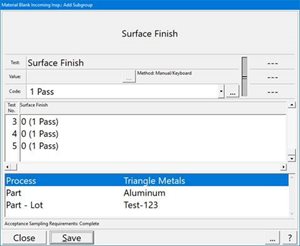

Once the inspection is complete and I have entered all my results for Surface Finish, the Items Remaining changes to Complete:

Next, I click Save. If the sample has satisfied the requirement and has Passed, the following window displays:

The software also has a report that can let the user know what remains to be tested on that Part/Lot.

Here, you can see that Surface Finish is complete (green with the word Pass) in the Status column. The remaining tests are highlighted in Yellow, indicating that they are incomplete.

This is the basic data entry for Acceptance Sampling. There are many additional configuration options that may fit your specific needs. Thanks for joining me for this close-up look at Acceptance Sampling. Please read on for more information about ProFicient software.

* DEFINITIONS FOR AQL, LTPD, CONSUMER RISK, AND PRODUCER RISK DERIVED FROM WIKIPEDIA.