Enact deployment strategy can be summed up in just a few words, or even one simple image. I see it as a mini-flowchart:

Easy as 1-2-3. That is what InfinityQS has always preached and Enact truly embodies this concept. And I hope this blog explains the concept, along with a lot more, as we talk about the real power of an Enact deployment: an easy, concrete, return-on-your-investment, proof-of-concept endeavor.

The Ideal Enact Software Deployment

The whole story I want to convey today essentially revolves around an “ideal first 90 days with Enact,” a brief look at how you should deploy this ground-breaking, native-cloud solution. A recent Boston Consulting Group article, “

Data-Driven Transformation,” talks about deployment strategies; it states that “transformations should start with pilots that pay off in weeks or months, followed by a plan for tackling high priority use cases, and finishing with a program for building long-term capabilities.”

That’s how we feel at InfinityQS. We want you to start your Enact experience with a simple, straightforward (pilot) process that you know can yield results in just a few weeks; this ROI will in turn help fund the next step—aiming for that “high priority use case.” Finally, continue on (expand/scale) in any direction you choose. When you’ve seen the software in action, you’ll know exactly where to turn next.

Have a Plan

When you have a plan, that means you’ve discussed options and decided on what’s best for your company. We suggest that when you deploy Enact you should have a pretty solid idea about what exactly is that first simple process you want to tackle, then where you might turn next when you see the concrete results, and where you eventually hope to go with the product.

To help you prove its value, Enact starts with a risk-free 30-day trial. That’s pretty cool. The way that things should work out is that at the end of the 30 days, it will be crystal clear to all your users of Enact that you have a business case and justification for continuing the Enact subscriptions. That’s the goal. So, if you map out the first 90 days, from 30-day risk-free “pilot” to extending to an equally simple second step, and then to scaling…your Enact experience should be solid and productive and, dare I say, eye-opening.

You should see return on your investment, ways in which you can expand Enact’s use, and many ways in which Enact can help you control your processes and improve quality at your organization. That’s the plan. So, where to start?

Starting Out with Enact

We suggest you pick a specific production line, or family of products, something small that you know needs attention…and start with that. In my experience, many people focus on just collecting data. And they don’t start small. They try to build out their data collection across everything. (

See how Enact handles data from lots of different sources.) Then they put those out on the floor, get some user feedback, and see that they need to make some changes…sometimes a lot of changes. Then they finally get to reporting, and that’s when I hear things like “We thought we knew what we wanted, but now that we actually see the data, we see that we missed the mark in some areas and found opportunities we weren’t planning on.” The result is that they will then need to go back and rework many of those data collections.

To begin your Enact experience, I think you need to alter your focus a bit. Away from just data collection. Think about the key result you’re trying to achieve. A meaningful result that improves your products and your business. Things like reducing scrap, rework, giveaway, and defects can have a quick, significant impact. I suggest focusing on the Enact process model and incorporating

manual data collection. Really keep it simple. The point here is not to avoid collecting data; it’s to collect the

right data.

The process model is unique to Enact. And it’s a game-changer. I suggest you start with one process model, which might be for just a handful of parts, and then put it out on the floor and start getting user feedback immediately—within a day or two. Find out from the shop floor people how the data collections are working. Any user feedback you get is going to help you with anything else that you do going forward.

(See more about the Enact Process Model on our website.)

The Process Model

Process models illustrate how materials are transformed through operations to create an end-product and where data collections are performed to verify quality. Look again at the one pictured above.

These dynamic diagrams show you exactly where and when various materials (represented by inputs) flow into operations to create outputs. You can combine and modify process model elements to create a visual process map, from raw materials all the way to finished goods.

With your first process model and data collections in place, you and your managers will start seeing the results immediately.

Review the SPC Data

Reviewing the reports that you generate will help you quickly make determinations about what needs to change, if you need to shift gears or collect data on something else, or in a different way.

At or around 30 days, you (as the Enact admin) should be comfortable saying “Yes, we are collecting the right information. We know what we’re doing. We like what we’re getting.” You can then take this knowledge “upstairs” and show the executives how this small usage of Enact can pay for the next phase of deployment. Any system needs to pay for itself in order to justify using it. Enact does that…and then some.

By starting small, and using the process model, that first month with Enact becomes a positive experience. You are on your way to not only proving return on your relatively small investment, but planning the many ways in which you can expand your use of Enact—ways in which the product can simplify things and save you money across your production lines.

Now that you have a built, functioning process model, the next logical step is to utilize Enact with a similar process. Allow me to explain.

Next 30 Days

So, let’s assume you’ve done everything I’ve noted above. You’ve had Enact for a month or so. And now it’s time to take that next step: stretch your use of Enact to another process, either upstream or downstream, or some other simple (and similar) process, whatever you like. The recommended strategy is to re-use the process model you’ve built on similar lines. But you can really go anywhere.

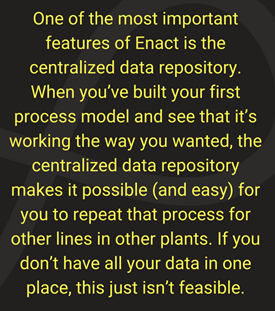

Reusing the Process Model

Let’s say you have four similar production lines, and you’ve just used Enact’s process model for one of those (starting small, like I suggested). Enact makes it easy to now use

that same process model—and its accompanying data collections and dashboards—for the three remaining production lines. Enact is built for this.

Let’s Go Downstream

One “can’t miss” choice is to continue

downstream. You have just put your product in a box or bag, or the liquid in a bottle, and now you can move on to the packaging piece of your manufacturing process.

…Or Upstream

Or perhaps your concern is the raw materials you use, or the incoming inspection; pieces like that can be added

upstream to your original process.

It’s easy to see in the process model above that you can extend the already-built process in either direction. Moving directly upstream or downstream from your original process model is an attractive way to go because it makes so much sense. You start with the existing process model and you just add to it. Enact is built for this type of expansion.

…Or Anywhere Else

If you would rather not go upstream or downstream, say, you’d rather go to a completely different process, or to a particular "problem area" in your manufacturing, that’s fine, too. There really is no rule as to what exactly is the next best move for Enact; it’s about getting value from the system.

For example, let’s say you started with filling and are now ready to move to packaging, but your operators inform you that this is a particularly busy time for the packaging group and there’s no time for training. No problem, you can move to another part of your operations and come back to packaging later.

Since we’re getting pretty deep into this, let’s take a moment to summarize:

- Start with a simple, straightforward “pilot” process—a specific production line or family of products—using the Enact process model

- Manually collect data

- Get feedback on the process model and data collections from the users

- See the results—generate and review basic reports that you can use to justify the next step: adding another line or process (by re-using the process model)

Time to take that next step, scaling your quality solution during that last 30 days or so.

Scaling—and I Don’t Mean Fish

It’s easy to take what you’ve done so far and expand it to an entire, complicated process, or across all your lines for a particular product.

Scaling means different things to different organizations. There are several general strategies that can be used for different types of scaling.

Standardization

Before discussing a few of these strategies, all organizations need to spend some more effort planning for standardization. This is critical because a standardized system is much faster to deploy (and maintain!) than one that is highly-customized. What kinds of things need to be considered with standardization?

- Metrics – Is everyone using the same quality metrics to know what success looks like? The most likely answer is that everyone should, but that may not be the case.

- Analysis methods – Is everyone looking at the data in the same way? It’s not uncommon for different production lines or sites to look at the same data using different methods. Sometimes this is a result of legacy practices and other times it’s a result of different metrology equipment, etc.

- Naming conventions – When using a centralized system, it’s critical that everyone knows the proper naming conventions, what’s shared, what can be customized, etc.

- Work practices – For a given product or process, does everyone perform the same checks? Again, the answer here is ideally “yes,” but often it’s not the case. Many times, the differences come from an issue you had in the distant past that has been solved, but the “short term” practices put in place to deal with the now non-existent issue have continued “just in case.”

While there are no hard and fast rules on this, the original statement stands: a standardized system is much faster to deploy.

Scaling Methodologies

Once standardization has been addressed,

how to scale can be considered. Here are some common strategies:

- Reuse – The fastest scaling has already been discussed above and Enact is designed to provide the maximum benefits to a standardized deployment. If you manufacture the same products on many production lines at many facilities, a standardized deployment can be shared instantly with those production lines.

- Expand a process model – The next fastest way to deploy is to expand a process model to accommodate products similar to those you piloted. This works great in highly standardized environments, or where a large family of products is made in a similar way.

- Create similar process models – In organizations that offer diverse products, things might not be done the same everywhere, but there will likely be similar operations. Focusing on these areas will allow the lessons learned from the first process model(s) to be applied and tweaked as similar operations are deployed.

- Upstream/downstream – This is mentioned above and is particularly effective for products that are either highly problematic (e.g., high defective rate) and/or high value. Creating process models upstream/downstream may be more involved than replicating the first process model, but this may be the fastest route to getting the most value from Enact.

This isn’t a comprehensive list, but it should give you some ideas on how a well-thought-out pilot can quickly provide benefit to the entire organization. While it isn’t a scaling methodology, I have to mention two other items that change when you deploy a cloud solution like Enact: hardware and licensing.

Hardware and Licensing

These are two items that companies often overlook when making the shift to a cloud-based system like Enact.

With a cloud solution, deploying to users across sites is no more difficult than within a site because there are no servers, databases, etc. (hardware) to “stand up” in advance. You also have the added benefit of choosing a wider array of lower cost devices because all you need is a browser.

Licensing offers a similar benefit in that it is a monthly subscription. No longer do you need to figure out pricing tiers, groups of users, etc. It is simply a matter of assigning licenses to the users and devices you want to access Enact and then using the system.

In Closing

So, there’s our ideal first 90 days with Enact. Start small, get success, and expand. You’ll find that the more you use Enact, the more it pays for itself. And the more time you spend with Enact, the easier it is to use. You’ll never look back.

Learn more about

Enact.