We’re all familiar with the term “workflow” in manufacturing—the sequence of processes through which something passes from initiation to completion. Event Workflow functionality in the Enact

® Quality Intelligence platform enables operators, quality engineers, supervisors, and others to respond consistently and effectively to process- and quality-related events.

Event Workflow captures valuable contextual information that can be used by anyone in your organization to better manage or prevent similar events in the future. In short, Event Workflows are intended to give guidance and reduce confusion.

For this blog, I’m going to focus on the three aspects of Event Workflow that make it such an effective tool: compliance, clarity, and consistency.

The Enact Event Workflow

Specifically, Event Workflow in Enact is the ability to stipulate rules for how the organization reacts when an event occurs. By “event” we mean data and timing violations.

- Data violations include manufacturing limits (specification, reasonable limits, net content control limits, etc.), statistical violations, etc.

- Timing violations include missed or late data collections and checklists.

You may define any or all of these to be considered exceptions to your day-to-day operations that occur on the shop floor. And, let’s face it, these types of violations happen to everyone in manufacturing.

(Click to see the animated Workflow image below.)

Setting Up Workflows

We set up workflows so that a group of individuals, such as operators, quality engineers, or supervisors, can be

required to take some sort of action based on an event—we can require event codes and/or event comments. Event codes are pre-defined lists of things like root cause, action taken, required maintenance, supervisor/manager event review, etc. Using lists of items ensures consistency and makes it easier for users because they can only select from a preapproved list of items. Event comments are just as they sound, free form comments to capture additional information.

If the word

required makes you wince, these same items can be listed as

optional or

not allowed for these roles. This makes things easier to not only ask someone for something specific, but also to prevent them from picking an irrelevant option.

The point being that these are repeatable, required actions for people to take when something happens during the manufacturing process.

General or Specific?

You can make event workflows as specific or as general as you want. In practical terms, that means that for all your lines you could set up a

general workflow for

all spec violations. However, if you have unique operations that have unique requirements (for example, filling), then you could set up a

specific workflow for spec violations on the filling line. Make sense so far?

Compliance

An important aspect of event workflows in Enact is its adherence to accountability; hence, it is important for compliance purposes. Event workflows can be assigned to specific roles. These assignments can be mandatory or not. For example, a worker may be required to take an action like enter a reason code, while another worker may add a comment based on an observation.

Appropriate event codes are then assigned to a workflow. This reduces the number of event codes from which a user must make a selection, keeping things efficient for the operator, technician, or manager.

Event workflows then can be assigned to a static or dynamic list of manufacturing processes. Enact continuously scans for possible events and sends out appropriate notifications of the event. Events with assigned workflows will also send out additional notifications to those workers or managers assigned to the workflow.

The point is that you control who is accountable for certain event codes. And

from a compliance standpoint, accountability is crucial.

Clarity

In terms of usability, an event workflow adds a level of clarity.

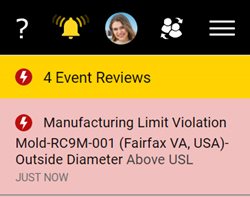

When an event occurs, the Event Review Banner displays the number of open events assigned to each Enact user. Also, the notification icon displays as a “ringing” bell, which indicates an action is required of the user:

Users can click on the Event Review Banner to bring up more details on the event through the Event Reviews page. This page lists all events that require action by the user. Only events with required actions are listed.

To learn more about this functionality, please visit the

Enact help system and view this

eLearning module (and so much more).

The benefit of visual clarity for event workflows is obvious: nothing is left to chance, and it’s easy for users to see what is happening—and what they need to do—at a glance. This provides clarity for the user expected to take an action, but this also provides clarity for those that need to review if the right things are “getting done.” Clarity for supervisors and managers is key, as they are often held accountable for the right actions being taken.

With the addition of event workflows, we now know what to expect for each event, meaning events can now be categorized as

open or

completed. As a supervisor or manager, it is likely a critical action for me to know if anything is left open before completing my shift or work day. One quick look at a Process Event Pareto can tell me if there are any open events that need my follow up before leaving for the day.

Consistency

The importance and consistency that event workflows bring to users of Enact cannot be overstated. When you define what workers need to do when a particular event occurs, you have essentially set up a best practice.

This is crucial for management, for it brings peace of mind that every time an event occurs it is handled in the same way—by every worker, on every shift, in every facility. Another benefit of consistency is with analysis. By having all users select from the same list(s) of event codes, analyzing things like which event codes happen most often and being able to investigate that across production lines, products, etc. is critical to solving problems.

Reusability

Let’s say I have seven filling lines on my shop floor. I know that, because of workflows, my people are all going to respond to things in the same way across the board.

Like many features in Enact, workflows were made to be reusable by the entire organization. Let’s think of this in a very practical sense, and thereby clarify why it’s important…

Rather than a plethora of lists—created by a variety of operators—containing the causes for all the issues I can have on the filling lines, Enact keeps a single, self-contained cause list, which everyone uses. This cuts down on the chances that the operator for filling line 1 responds differently to an issue that filling line 2 may have experienced. While this is very powerful for analysis (“How many times did we have to clear clogged nozzles on our blow molders?”), you can keep it simple for the operator by filtering those lists differently based on their process, so they aren’t presented with irrelevant options (“Why did someone say they reset the clamp on Molder 7? We only have clamps on Molders 8-12.”).

Conclusion

The three aspects of Event Workflow that make it such an effective tool—compliance, clarity, and consistency—are also the attributes that make Enact so powerful as a manufacturing quality tool. Manufacturers can rely on Enact to be visually engaging and easy to use, to help them keep their operations standardized, and to enable them to cut down on audit issues.

There are many manufacturing software products that do workflows, but nobody does it quite like we do and that can make a big difference.

Please read more about

Enact.