What is SPC? If you are new to

statistical process control, this can be a daunting question. SPC is everywhere in manufacturing. Yet there may still be some who either don’t know about it or are intimidated by the concept. I mean, after all, “statistics” is right there in the name, right? Some folks have bad memories of advanced math in school.

The answer to “what is SPC?” is not simple, but it shouldn’t be scary either. Hopefully this blog will demystify the term, alleviate any fears you may have, and answer any lingering questions.

Why Should I Use SPC?

Manufacturing is a highly competitive industry. We all know that. And manufacturers are only as good as their processes. Your organization is judged by the quality and volume of products that your processes produce. But there are struggles, most notably:

However, you may be looking for better methods to not just fix problems but prevent them; not to just eliminate variations but improve the bottom line; and not just improve quality—but never ship a bad product again.

Let’s look at how using a modern approach to SPC methods using real-time quality data can help you achieve the operational excellence you need—but even more importantly, let’s look at how that transformation you’re looking for is actually within your grasp.

Defining SPC

Here at InfinityQS, we define SPC as a “methodology for measuring and controlling quality during the manufacturing process.” We’re known as the SPC experts in the manufacturing industry. It’s our bread and butter, you might say.

We look at SPC as the culmination of all the aspects of maintaining and improving quality in your manufacturing environment, including:

Let’s look at each of these aspects of SPC, and how they fit into the overall scheme, and we’ll thereby demystify the term.

Modern Data Collection

SPC data collection can set the stage for significant process and product improvements. Your SPC system can become the foundation for greatly reducing risk, waste, and defects. But if you want the system to work right, you’ll need to take a hard look at how you collect data.

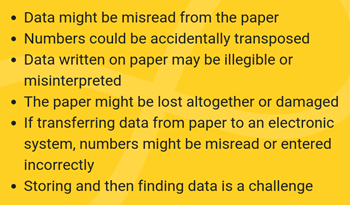

Ditch the Paper

Manual data collection has the propensity to introduce errors:

Operators enjoy working with software that makes data collection fast and easy. They will thank you if you implement a system that lessens their burden and eliminates the hassles associated with juggling paper and spreadsheets.

Time to go digital. As you move to a digital world, there are data collection technologies that you need to include.

You’ll want to consider electronic data collection features for hand-held gauges, programmable logic controllers (PLCs), pre-existing databases, and manufacturing execution and enterprise resource planning systems. Those types of data should be able to be captured automatically, without engaging an operator.

Additionally, bar-code scanners are a fast, convenient, and inexpensive means for entering defects data or associating information (such as purchase order numbers, lot codes, and other descriptive fields) to data that are being captured by operators and inspectors.

Operator Notifications and Alarms

SPC works best when your system provides reminders to operators and inspectors when data collections are required. That’s critical. You need to know if those data collections didn’t occur as scheduled. If data collections are missed or skipped, you should be notified, and reports should tell you what was missed and why.

For example, say you need data from a specific product feature to be collected each hour. Instead of asking your busy operators to remember to gather data every 60 minutes, they can instead concentrate on their production tasks and forget about watching the clock, secure in the knowledge that they will receive a notification when it’s time for a quality check.

Beyond Data Collection Notifications—Keeping an Eye on Quality

Your SPC system can alert your team immediately when issues occur, or violations are triggered on the shop floor.

Real-time alarms can help you mitigate the damaging consequences of undetected excessive variation, unsafe products, unbalanced ingredients, and more. Whether visual or auditory, alarms catch the user’s attention and reach them

wherever they are,

whenever a violation occurs.

Prioritizing Your Quality Efforts

So, what do you do with the data that didn’t trigger any alarms? What do you do with the huge amount of data that falls

within spec limits?

Your SPC system stores data in a centralized data repository. If it doesn’t, it should. Here’s why…

Intelligent aggregation can be performed when all your data are in one place. And when you aggregate large amounts of data across multiple lines or plants, you see the

big quality picture. And that can drive strategies that can transform organizational performance.

Imagine rolling up and viewing all that data on a single screen. That screen highlights where your company has the greatest opportunities for improvement. You can now determine where to initiate improvement projects that could make the greatest positive impact on quality and costs.

Essentially, we’re talking about

prioritizing your quality improvement efforts. We’re not talking about analyzing data that triggered alarms. Aggregating

all your quality data—even the values that fall within specification limits—will enable you to pinpoint and prioritize where to deploy your scarce and valuable quality experts and resources to generate the biggest bang for your buck, as fast as possible.

It’s a brave, new world.

Analyzing Your Data for Useful Information

Your Quality Professionals, Engineers, and Six Sigma teams are the analysts who extract data gold in the form of pertinent information from the big quality picture. The big quality picture does not provide the detailed information that can be acted upon; instead, it’s used for guidance and prioritization for where to focus improvement efforts.

As adept as analysts are at extracting the details, they first need to be directed to where opportunities for improvement lie. The prioritization you just performed, in which you aggregated all your data and identified the high priority items, is your map which highlights opportunities for improvement, and which defines where your analysis experts need to dig.

And let ‘em dig! You know your SPC solution can help them uncover gold hidden in your data. Their success means that you will know exactly where the issues lie, and how the most impactful improvements can benefit your operations.

Your analysts should be able to identify process improvements that will enhance quality in a specific area, which can then be turned into best practices that can be applied

across the enterprise. In this way, your data miners will be able to break down your priorities into information that can be acted upon to help transform performance.

Reporting Your Results

Now your data experts need to take that analysis they’ve performed on your quality data and report to the local plant personnel: operations directors, plant managers, quality managers, and other operations personnel. They should have one goal in mind:

convincing the local plant people that the valuable information they’ve uncovered will dramatically improve their operations.

The information they need to convey is important. It’s organization-changing stuff. The reason that data experts need to be

convincing, is to get

buy-in from plant personnel.

The real work, the change that needs to occur within any organization, takes place at the plant level. The folks on the floor put the plans conjured up by the data experts into action.

Transforming Your Business

So, your quality experts have made their pitch—a variety of recommendations for improvement—and the recipients, the local operations people on the shop floor, are skeptical. But, they’re convinced enough, and maybe even curious enough, that they want to try something (maybe just one small thing) on a limited basis.

Let’s say they try one of the recommendations, gather the data from a line or across multiple lines, and compare the results to the data prior to deploying the recommendations. This is generally when they have their “Aha!” moment. They quickly understand that data can be converted into incredibly useful, operationally-beneficial

information—even when generated by corporate people (who reside

outside of the manufacturing plant).

Think about the benefits that moments like these can have for an organization. Suddenly people realize that the corporate quality experts are truly interested in supporting plant operations. They realize that everyone really is “in this together,” and perhaps they even see what

they can do to support company success.

It is very satisfying to see that data, that

information, put to use to provide valuable insights. And success—as we all know—brings people together, helps everyone get involved, and makes each and every one of your employees an engaged stakeholder.

Closing

So, there’s the answer to “what is SPC?” It’s not simple, but it shouldn’t be scary any more either. Remember, you’re only as good as your processes. And your organization will be judged by the quality and volume of products that your processes produce.

Now that SPC is demystified, you can see that it can help you to not just fix problems but prevent them. On the plant floor: reduce waste, defects, rework, and scrap; improve product quality; and eliminate variation in processes. At the corporate level: improve the bottom line, reduce risk, and transform how your organization looks at quality.

Learn more about

InfinityQS quality software.

Learn more about SPC and quality; read some of our other informative blogs: